ANCHOR CORE TECHNOLOGY BENEFITS

Improved Stability

Pre-loaded energy

Increased Durability

Carbon free

In a competitive industry, mainly focused on profits and reducing margin costs, we decided to go off the beaten track and push for a solution to squeeze the maximum performance out of the used materials. We are proud to announce that this ended up like one of the key developments in board sports of the decade. We have not only been able to set new records in the most important figures for board sports (dynamics, damping, torsional stiffness, break durability), but also to do it using quite less material than in competing products. It's important to highlight that, using this technology, no extra synthetic layers (like carbon fibers) are needed to achieve the maximum performance. Add also the increase in performance and durability of the boards, and you get a fraction of the environmental impact that traditional boards have.

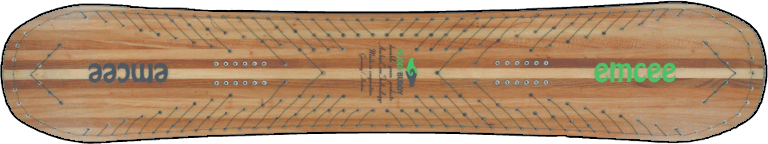

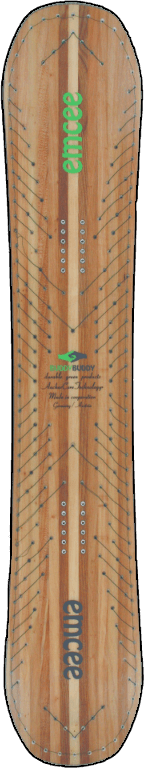

The key aspect behind AnchorCoreTechnology® is the union of the top and bottom fiber layers by anchor points. They go through holes in the core connecting the fiber layers together. Our research has shown that, placing these points in specific positions, is possible to improve the different dynamic characteristics as needed for each board section.

Ok, that's a lot of talking, but let's try to prove our speech with facts. And no better way to start, that explaining the basis of the technology with simple words. Let's have a look to the slides below to check how our technology compares to a hanging bridge.

FINELY TUNED BOARD DYNAMICS

The most important parameters that define the board's dynamics are flex, damp and snap. Their values define the board's performance and can be used to differentiate a great board from the rest.

Flex

The flex is probably the first thing we check when choosing a new board. In general, flexible boards are easier to ride, allow sharper turns and have improved manoeuvrability, what makes them the preferred option for freestyle riders. In the other hand, stiff boards are difficult to control and not be very responsive. However, they deliver better stability and performance at high speeds, becoming the election for freeriders and speed lovers.

We can differentiate two types of flex:

- Longitudinal flex is the bend that the board gives from nose to tail. It is the kind of flex we all like and make our boards better for landing tricks, hit obstacles with precision or balancing on the nose or tail.

- Torsional stiffness goes from toeside to heelside (across the width). It measures the resistance to twist (tip and tail rotation in opposite directions). This is not desired and is very important to keep it stiff if we want to hold the edge grip at high speeds or prevent bites in carved turns.

Damp

The damp measures how well the board absorbs and neutralize bumps and vibrations. Again, we can differentiate two types of damping:

- Low frequency damping acts as a shock absorber, neutralizing the bump vibrations before they reach the rider. It also increases the grip, as it allows better board contact with the road or the snow. The better the board is at absorbing all the low frequency vibrations, the smoother it feels when riding uneven ground, and the less fatigued your legs are going to be. It is the kind of damping we see in very flexible boards.

- High frequency damping influences the board stability at high speed. It is required to prevent board vibrations when going very fast, also known as speed wobbling. This is the damping that comes with stiff boards.

An easy analogy for both types of damping can be done with cars. Race cars feel very stable in perfect roads at high speed. They have very good high frequency damping. Take them out of the circuit for a ride home and any small bump in your way will not be fun anymore. It will feel rigid and bumpy in ordinary roads because the low frequency vibrations are not neutralized. The contrary will happen to a normal familiar car, they are good for the bumps (low frequency) but very unstable at high speed (high frequency vibrations).

Some more details on how the vibrations are neutralized using our technology can be found in the improved stability section.Snap

This is somehow related to the energy the board is able to absorb and give back. It is commonly described as the "liveliness" of the board. A good snap will be more fun, helping us to ollie higher, improving jump landing and letting us recover from falls and off balance turns better. This is a bit more complex topic and we cover it in details in the pre-loaded energy section.

Traditional board types

Usually there is a trade off between the different types of flex, dampness and snap. In traditional boards construction, increasing the longitudinal flex also improves the low frequency damp but reduces the torsional flex, the high frequency damp and the snap. This is why we see so many different board types in the market, because adjusting those variables independently has always been a big challenge for manufacturers. Is not easy to improve all the parameters together. In the boxes below you can see the traditional types of boards and how they compare to our technology:

Traditional freestyle

Longitudinal flex: GOOD

Torsional stiffness:

BAD

Low freq

damp: GOOD

High freq

damp: BAD

Snap:

BAD

Traditional speed

Longitudinal flex: BAD

Torsional stiffness:

GOOD

Low freq

damp: BAD

High freq

damp: GOOD

Snap:

OK

Traditional all-around

Longitudinal flex: OK

Torsional stiffness:

OK

Low freq

damp: OK

High freq

damp: OK

Snap:

OK

AnchorCoreTechnology®

Longitudinal flex: GOOD

Torsional stiffness:

GOOD

Low freq

damp: GOOD

High freq

damp: GOOD

Snap:

GOOD

The search for the perfect all-around board

The perfect board would be longitudinally flexible and torsionally stiff, have high vibration damping and feel snappy. Current solutions for high performance boards are based on adding extra layers based on highly contaminant materials as carbon fibers. Unfortunately that kind of solution means to increase the weight and resources needed to build each board.

AnchorCoreTechnology® is able to improve all these variables at once in a simple and elegant way. Placing the anchor points in strategic areas, we are able to adjust the parameters independently one from each other. This way, every section of the board can be finely tuned by adjusting the longitudinal flex, torsional flex or damp as desired. The way it works is simpler than you might expect:

- The more anchor points you put on the same fibre, the stiffer it gets. Using triaxial fiber the lines run on three directions, what allows us to differentiate longitudinal and torsional flex:

- 0° fibers run along the board and affect the longitudinal flex.

- +/-45° fibers run diagonally and are related to the torsional stiffness.

- The more individual fibres you anchor, the more effective the high frequency damping.

- The superior snap is achieved by preloading the fibers during the fabrication process. This is an important feature and is explained in details in the pre-loaded energy section.

Sum all of this up and we can add stiffness, damping and liveliness (independently) in the direction and specific area we want. The flexibility of our method is so high, that you can be sure to get the best all around boards in the market. Flexible, snappy boards and stable at high speed. No other method allows to adjust everything in the board as finely as this technology does. You can have a look below, to learn how we apply all of this theory to the design of one of our snowboards.

Please select/unselect the groups you want to show

-

Board outline: Many individual fibers are anchored here to improve the damping and increase the resistance to delamination in the borders.

-

0° fibers: Many anchors in the same line around the bindings, this improves the damping and increases the board stiffness where is needed (around the feet).

-

+/-45° fibers: The torsional flex is increased proportionally from the board tips to the center.

-

Fancy tip arrows: together with the outline anchors, the arrows use the +/-45° fibers in the tips to project a stiff area in the nose and tail. This improves, even more, the energetic response of the board.

-

-

+/-45° nose-tail energy area projection

-

+/-45° nose-tail energy area projection

IMPROVED STABILITY

The stability of the board at high speed is mainly determined by the torsional stiffness and the high frequency damp. Until now, it wasn't really possible to manufacture a flexible board with those characteristics (torsional stiffness + high frequency damp), leaving high-flex boards for beginners and freestylers only. But reducing the flex has the collateral effect of removing the low frequency damp. No one can deny that the board's capacity to absorb bumps in the terrain (low frequency) is a very important factor to get a smooth and stable ride. And let's not forget that the flex increases the contact with the ground and, therefore, the grip. Unfortunately all these flex benefits are lost in the stiff downhill boards (just try to ride them in a bumpy place).

How can we keep the longitudinal flex, torsional stiffness, low and high frequency damping all at once? AnchorCoreTechnology® is the answer. Our boards absorbs low frequency bumps in the terrain (thanks to its flex) while providing a direct, predictable and agile turn at any speed (by keeping the torsional stiffness). This is the only solution that gives the maximum ride stability and edge grip while keeping the board light and agile. But what happens with the high frequency damp? An inefficient high frequency damping is the main cause for speed wobbles and instabilities when going fast. Well, this is also handled by our anchor cores. The way it works is easier described by a guitar string:

The anchor points act like your finger on the guitar string, stopping specific lines from vibrating. Placing them on fibers that are likely to get vibrations, we have a very effective vibration damping. This is proven to be even superior to other specialized vibration damping solutions (like adding oil based rubber dampings).

But the vibration in the guitar string is a standing wave, however, we get travelling waves going across a board. That means that if the front of the board hits a bump, the 0° fibers will start vibrating, and they will keep swinging up to your front foot. If the bump was heavy enough, the vibration will continue through the whole board and to your back foot.

Have a look to the animation below to see how the travelling waves are attenuated as they find the anchor cores on their way:

In the next recreation you can see how a traditional board is getting a lot of vibrations after hitting a stone in the road, even the back foot is affected by the bump. On the other hand, the board using AnchorCoreTechnology® is successfully dissipating the energy from reaching the second foot.

PRE-LOADED ENERGY

The energetic response is a very important feature related to the board's performance. It is also known as snap or liveliness of the board. Among other things, it dictates how the board will absorb the energy to allow a clean jump landing, or how it pushes us up to a big ollie. The fiber inside the glass layers are the main responsibles for the elastic behaviour you feel in the board. The fibers are capable to absorb the energy as they stretch, and then deliver it back while they return to their rest position.

An easy analogy could be a rubber band. It will behave very similarly as the board's fibers, absorbing energy when you stretch it and returning it back when you let it go.

Unfortunately, fibers come loose out of the box. You can see the ondulations in the picture below. Traditional board fibers are not stretched and, therefore, not ready to absorb energy.

Wouldn't it be perfect if the lines were always straight when you ride a board? no delay to start stretching the fibers and get them into the energetic phase, they would be always ready for action!! That is exactly what AnchorCoreTechnology® does: we pull the fibers in the fabrication process. This way they remain always straight and ready to absorb energy, whereas traditional boards require a small bending before their fibers are totally straightened. When other boards are still absorbing energy ours are ready. This makes them feel more snappy, lively and with better pop, absorbing a jump landing with less deformation, or helping to ollie higher when leaning to the same angle. You can see it better in the slides below:

In summary, our technology activate the fiber lines pulling them during the manufacturing process, producing boards ready to absorb energy straight away. This is done by state of the art machines using our exclusive and patented method. You can watch below, a simple animation of what we do with the fiber lines:

But traditional boards are still getting to their original shape even when the fibers are not straight. Yes, they do, but the flex outside the fibers energetic range is only due to the core properties and not controlled by the fibers. This makes the energy changes to be far from smooth and clean. That is why the fiber layers are in the board in the first place, to keep a nice and smooth flex, otherwise we would have a single material (core) board. While the fibers are not energy active the board dynamics are not as engineered, and this is what our technology does, it ensures the energy curve is always as designed, so you get the smoothest flow and ride in the market.

INCREASED DURABILITY

Everyone wants not only a good performance product, but also a durable one. The anchor connections between the top and bottom glass layers significantly increase the break durability.

Delamination is the main weak point for traditional board construction. It is basically the separation of the different layers and it occurs as a consequence of impacts, crashes or repeated cyclic stress after prolonged use. You can find an example in the picture below:

AnchorCoreTechnology® connects the top sheet to the bottom sheet and therefore doesn't allow a delamination of one of them. Our break durability figures are even better than boards with carbon and kevlar fibers. If eventually it does break, it still doesn't collapse. All the fibers will remain connected to each other and only the core will crack. That means the board will still be usable to take you back to the bottom of the hill, a fact that can save lives in heavy backcountry crashes.

But we do not need a big crash in order for delamination to occur. Let's try to explain how delamination will happen after prolonged normal use, without need for intense material abuse. We like boards to have some flex because that way they are more fun to ride. We also make turns, ollies, tricks, etc. All these movements will slightly bend the board every time, and this bending will happen thousand of times with every ride. This stress will cause forces to affect the fiber layers in different ways. The bending arc will be longer in the bottom of the board, causing the bottom layer to stretch. On the contrary, the top arc will be slightly shorter, causing the top layer to compress. However, due to the glass fiber properties, both layers will react trying to return to their rest width and position. The bottom layer edges will suffer forces prone to delamination, the same as the center of the top layer. As a result of this continuous stress the layers will eventually separate from the core. All of this might be easier to understand checking the slides below:

As a corollary to this explanation, you can quickly check at home how this applies to something as simple as a notebook. Just grab one, firmly press the borders and bend it several times. You will see how, eventually, the top and bottom pages will react as explained here. You can see what we mean in the pictures below.

We are so sure of the durability improvement when using our technology, that we can offer a 5 year warranty against delamination or our technology failing on all BUDDYBUDDY boards with AnchorCoreTechnology®

CARBON FREE PRODUCT

Even when high end board manufacturers are aware of the environmental impact that using synthetic carbon fibers brings, they think there is no alternative solution. With this technology we are able to prove them wrong. Some of the problems that carbon fiber layers bring are:

- Carbon fibers require an immense amount of energy to produce.

- The emissions during carbon fiber production are very contaminant and contribute to global warming.

- The final material is carcinogenic and very contaminant.

- It is not biodegradable and nearly impossible to recycle.

Several industries are already aware of the problems that using carbon fibers brings and are trying to deal with them (bikes, automotive, aerospace). Today, the manufacturing of carbon fiber is heavily regulated by the environmental community and producers are continually looking to reduce energy demands of this heat intensive process. The oxidation and carbonization furnaces and industrial ovens have the potential to emit hydrogen cyanide (HCN), ammonia (NH3) and volatile organic compounds (VOCs). Some of these pollutants are immediately dangerous to human health, even in very small quantities. Other pollutants of concern for carbon fiber producers include Greenhouse gases (GHGs) such as carbon monoxide (CO) and nitrogen oxide (NOX). These emissions not only contribute to global warming but also have a direct correlation with the manufacturer's consumption of energy. Will we still support the carbon layer board construction when, due to global warming, there is no snow left in the mountains? We have to start measures right away if we want to avoid this in the foreseeable future.

However, despite of the facts listed above, board producers claim that is not possible to reach the performance figures needed without using this material. A non preloaded fiber reaches only about 15% of it's theoretical performance, this is not enough for today's standards and carbon layers have to be added. Thanks to our technology, we are able to preload the fibers and get much closer to the maximum we can expect from basic materials (as explained in the previous section), pushing their performance near the theoretical limits. That way we are able to get high performance out of less materials and, most importantly, using more ecological sources. Our construction produces very dynamic and ecological boards, while also keeping them light, playful, durable and top performers.